Adjustable speed eddy current drives and digital controls offer true system efficiency and performance

Dynamatic drive clutches on induction motors have been installed in water & wastewater treatment applications for many decades, primarily due to the inherent durability, simplicity, and reliability of Eddy Current technology. Even though variable frequency drives (VFDs) gained popularity in the 1980s, real-world experience at facilities around the world has proven that only Dynamatic can bring TRUE system efficiency to your water & wastewater operation. “True efficiency” is defined by three important cost factors: capital costs, energy costs, and cost of ownership.

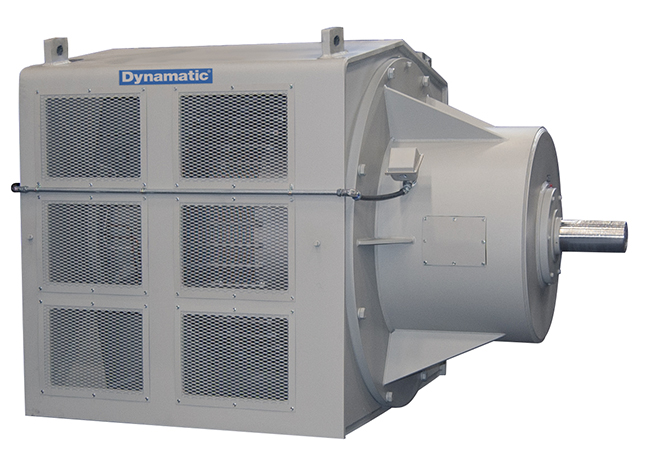

Salient Pole

Eddy Current Drive

AT Vertical

Eddy Current Drive

SPC Eddy Current

Coupling

Save up to 65% on capital pump-drive system costs

For decades, Dynamatic® systems have outlasted and outperformed self-proclaimed “efficient” variable frequency drives in a wide range of medium voltage wastewater applications. In fact, a Dynamatic® Eddy Current pump drive system can save your municipality hundreds of thousands of dollars in capital costs alone. Savings are typically 50% to 60% compared to the initial cost of VFD systems in medium voltage applications.

Lowest energy costs for wastewater pumping applications

The operating efficiency of a Dynamatic® drive increases relative to the normal operating speed of a motor. This makes the Dynamatic® drive ideally suited to most wastewater pumping applications, which typically require controlled speed within the range of from 75% to 100% of the motor’s rated speed. In contrast, the operating efficiency of a adjustable frequency drive decreases across this range. In addition, VFD operating efficiency can be further diminished by added energy costs incurred by required ancillary VFD system components.

Minimize ownership costs with reduced maintenance, repairs and upgrades

Dynamatic® drives have been shown to outlast VFDs by as much as 6:1. Their rugged and proven reliable electromagnetic clutch design is highly tolerant of fluctuations in power quality. Unlike VFDs, Dynamatic® systems produce virtually no harmonic noise into your plant’s electrical system or onto the utility grid. By comparison, VFDs continue to be complex devices bearing higher ownership costs with shorter product life cycles. These significantly higher costs are attributable to quicker VFD product series obsolescence, faster parts obsolescence and earlier forced product replacements.

Achieve TRUE system efficiency with Dynamatic® Digital Controls

Dynamatic® EC-2000 Digital Controls are the perfect solution for new installations or retrofitting all brands of eddy-current drives. The EC-2000 control is a simple, versatile, digital, electromagnetic drive control featuring local and remote access to programmable run presets. The control is PLC and SCADA compatible, the outputs do not require separate external DC supply. Learn more about Dynamatic® EC-2000 controls.