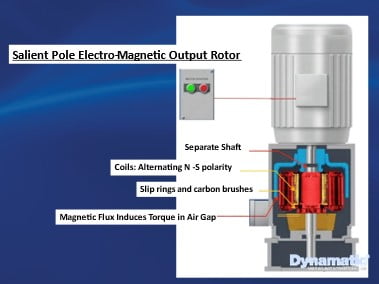

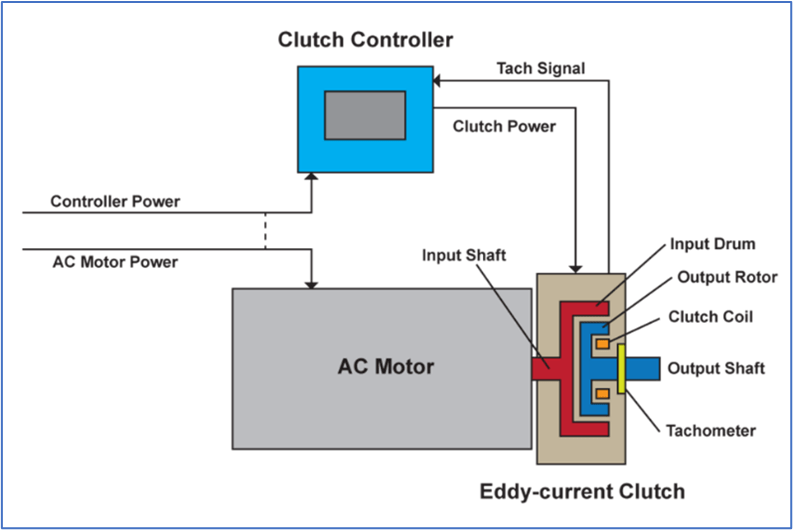

Eddy Current Drives uses eddy currents – loops of electrical current created by changing the strength of a magnetic field. As the drum turns and excitation current is applied, a torque is developed, and the output rotor drives the load.

In an Eddy Current Drive, the motor and driven equipment are not physically connected. The Eddy Current Drive goes between the motor and pump and the input and output shafts turn independently. This allows for the motor to always be running at design speed, providing maximum cooling to the motor helping extend the motor life and the ability for multiple starts and stops eliminates peak demand charges.

The excitation current is from a single-phase low voltage power supply. It consumes about 1% of the power rating of the drive unit, this power could be sourced directly from the motor circuit or from a separate panel-board branch circuit. The drive comes with a small controller to interact with PLC and SCADA equipment. Speed control mode with tachometer feedback will regulate with in 0.5% of set speed.

Simplified power schematic of an eddy current drive

Advantages include small footprint, no environmental control or cooling – units can be outside, motors do not need to be inverter duty rated, Eddy Current Drives require NO expensive harmonic filters.

Eddy Current Drives are maintained much like a motor. Every 6-12 months: grease bearings replace brushes, if applicable, clean dust/debris out of enclosure.

With a typical life cycle of 40-60 years, Dynamatic drives are the longest lasting variable speed drive system if they are maintained properly.