Long life cycle and low maintenance costs in hostile environments

Harsh environments, such as asphalt and aggregate duty, are no problem for the dependable and reliable performance of Dynamatic DCD Drives.

DCD models are direct NEMA and IEC motor frame replacements for many eddy current brand models. Dynamatic DCD drives fit right in place!

Example Uses:

- Conveyors

Industries:

- Mining

- Asphalt

- Aggregate

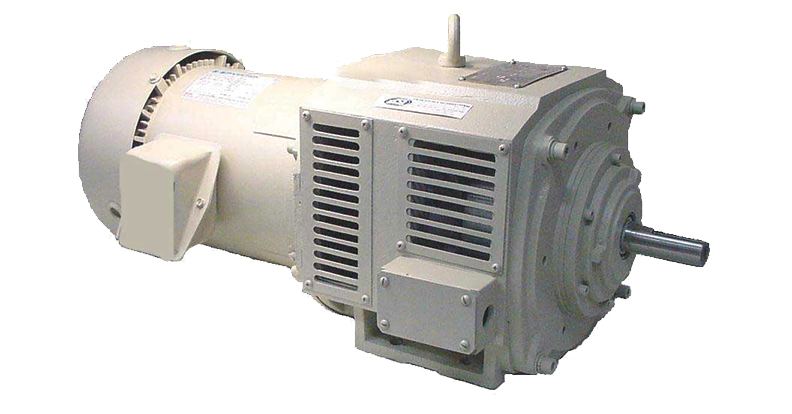

Dynamatic DCD Drives

DCD Drives are a simple low-cost solution featuring a TEFC AC induction motor, with multiple voltage and 50/60 Hz options. The C-face motor is flange mounted to the maintenance free Eddy Current coupling.

What is it?

DCDs are a combination of an air-cooled, adjustable speed clutch and a flange mounted AC induction motor. Simple, low-cost dependability that is readily interchangeable with models TCD and CD. DCDs transmit torque at adjustable speeds. There is no physical contact between input and output members. This results in smooth response, thereby eliminating shock and loading and extending equipment life. All drives have an integral tachometer generator mounted around the output shaft to provide feedback signal to the drive’s controller. The controller provides the DC excitation for the clutch coil. The feedback signal from the tachometer generator is used as a reference signal within the controller to maintain accurate speed regulation.